Menu

Forklift Chains

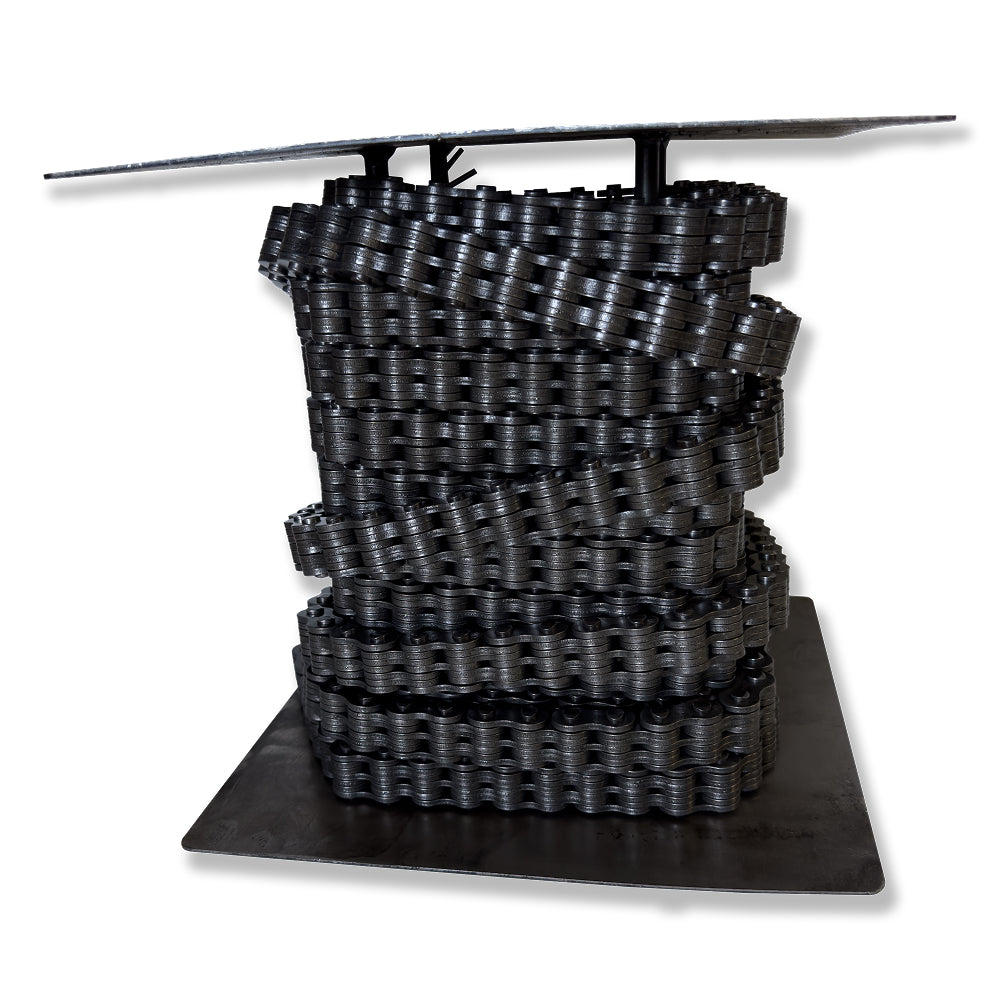

BL546 Leaf Chain 10FT – Forklift Masts & Hoisting + 2 Links

Quick View

Sold out

BL546 Leaf Chain 10FT – Forklift Masts & Hoisting + 2 Links

- Price

- $93.24

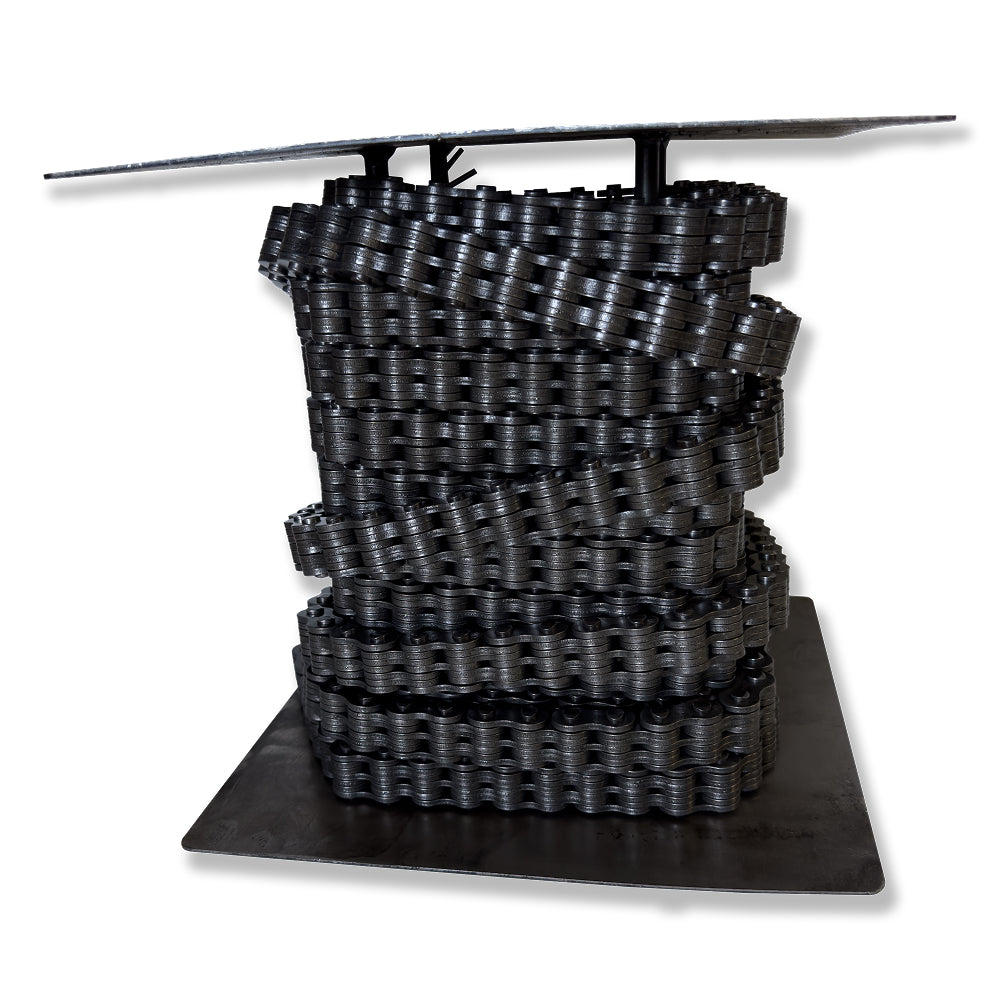

BL634 Leaf Chain 10FT – Forklift Masts & Hoisting + 2 Links

Quick View

BL634 Leaf Chain 10FT – Forklift Masts & Hoisting + 2 Links

- Price

- $98.70

BL634 Leaf Chain 50FT – Forklift Masts & Hoisting + 5 Links

Quick View

BL634 Leaf Chain 50FT – Forklift Masts & Hoisting + 5 Links

- Price

- $457.56

Forklift Chains Built for Lifting Strength and Safety

Forklift chains are critical components in the vertical lifting systems of forklifts. Designed to handle heavy loads with precision and control, these chains are widely used across industries such as logistics, construction, and manufacturing.

Typically built as “leaf chains,” they are engineered to withstand high tension, providing operational stability and safety in demanding environments.

Choosing the right forklift chain directly influences equipment performance, durability, and safety. That’s why it’s essential to rely on chains that meet technical standards and deliver strength you can trust.

At PGN Bearings, you’ll find heavy-duty forklift chains available in various models and lengths—engineered to perform under pressure.

Read More

What Is a Forklift Chain and What Is It Used For?

A forklift chain is a critical mechanical component used in the vertical lifting system of a forklift. Installed primarily in the mast, it is responsible for raising and lowering loads with precision, control, and safety.

Unlike standard transmission chains, forklift chains — typically built as “leaf chains” — are made of layered steel plates linked together with pins, creating a structure that’s both strong and flexible.

This design allows the chain to withstand high tensile loads while maintaining mast stability during repetitive lifting cycles and heavy operations. Compared to wire ropes, forklift chains are often preferred in industrial settings due to their enhanced durability, reduced maintenance requirements, and smoother vertical movement.

Whether you're loading, unloading, or lifting in high-demand environments, forklift chains deliver the strength and reliability your equipment needs to perform safely.

How Do Leaf Chains Work in Forklifts

Leaf chains work alongside the forklift’s hydraulic system to move the mast vertically. Made of interlinked steel plates, they offer strong tensile resistance — perfect for lifting heavy loads. Also, proper lubrication and correct tensioning are key to long-term performance and safety.

How to Choose the Right Forklift Chain

Choosing the right forklift chain is essential for safety and operational performance. Start by identifying your forklift model and the load capacity it requires. From there, you can select the most suitable chain type.

Chains like the BL546 and BL634 follow ANSI standards and differ in tensile strength. The BL546 is ideal for medium-duty tasks, while the BL634 is built for heavier loads.

Chain length also matters—10FT chains work well for standard operations, and 50FT versions are better suited for continuous or extended use.

Always opt for chains that include connecting links, making installation easier and reducing equipment downtime.

Forklift Chain Options Available at PGN Bearings

At PGN, you’ll find forklift chains engineered to meet various load demands across industrial environments.

All options are ANSI-compliant and include connecting links for seamless installation and compatibility with mast and hoisting systems.

BL546 10FT – Mast Leaf Chain with 2 Links

The BL546 is ideal for medium-duty operations requiring reliable strength and smooth performance.

With a 0.63" pitch, it delivers an average tensile strength of 84.5 kN and weighs 1.5 lb per foot. Built with a 4x6 plate configuration, it offers excellent durability under repetitive lifting cycles — perfect for active warehouse environments.

BL634 10FT – Heavy-Duty Forklift Chain

Built for high-load applications, the BL634 features a 0.76" pitch, an average tensile strength of 102.8 kN, and weighs 2.5 lb per foot.

Its 3x4 plate structure ensures enhanced durability and performance under demanding industrial conditions. Includes 2 connecting links for easy setup.

BL634 50FT – Long-Run Leaf Chain with 5 Links

Delivering the same specs as the 10FT version, this extended 50FT chain is suited for continuous use in large-scale lifting systems.

It comes with 5 connecting links and provides consistent strength and stability for long-run industrial operations.

Forklift Chain Applications Across Industries

Forklift chains are essential for vertical lifting tasks that require safety and precision. Their strength and durability make them a reliable choice across industries where heavy loads and constant movement are part of daily operations.

-

Warehousing and Logistics: In high-paced warehouse environments, chains help forklifts load and unload efficiently, supporting smooth operations and minimizing downtime.

-

Manufacturing and Industrial Production: Factories and assembly lines rely on strong chains to lift and transport materials between production stages, ensuring continuous flow and worker safety.

-

Construction and Heavy Equipment: On construction sites, where conditions are demanding and loads unpredictable, forklift chains provide the strength and stability needed for safe, heavy-duty lifting.

Maintenance Tips for Forklift Chains

Proper maintenance of forklift chains is essential for ensuring operational safety and extending equipment lifespan. Regular inspections allow early detection of wear and prevent costly failures.

Look for cracks, deformations, or signs of excessive elongation. A compromised chain can affect mast stability and pose serious safety risks.

Keep chains well-lubricated with suitable products to minimize friction and prevent corrosion. Also, make sure the chain tension is properly adjusted according to manufacturer specifications.

When replacing or performing preventive maintenance, use the correct tools and, whenever possible, consult professional support to ensure a safe and effective installation.

Benefits of PGN Bearings Forklift Chains

PGN Bearings forklift chains are engineered to deliver top-level performance, even in the most demanding industrial environments.

-

Each model is built with premium materials and manufactured under strict quality standards for dependable, long-term use.

-

High tensile strength and durability: Our chains handle heavy loads with stability and precision, maintaining consistent performance in repeated lifting operations.

-

Reinforced plates and precision-fit pins: Built with thick plates and accurately fitted pins, PGN chains ensure minimal wear and enhanced safety over time.

-

Compatible with a wide range of forklift models: Available in multiple sizes and configurations, all PGN chains come with connecting links for easy installation and are suitable for various lifting systems.

Choosing PGN means investing in fast logistics, operational safety, equipment longevity, and consistent performance.

Why Buy Forklift Chains from PGN?

Choosing the right chain matters — but choosing the right supplier is critical. PGN Bearings is a trusted name in industrial components, offering a combination of quality, fast delivery, and technical support. With U.S.-based inventory and efficient shipping, your order arrives quickly and ready for immediate use.

We also provide expert assistance to help guide your purchase and answer any technical questions before or after the sale. All of our forklift chains meet ANSI standards, ensuring safety, compatibility, and optimal performance for industrial use.

Whether you need a light, medium, or heavy-duty chain, PGN offers the ideal solution with connecting links included and easy installation.

Reliability, durability, and expert support — three reasons to trust PGN for your lifting needs.

Frequently Asked Questions about Forklift Chains

1. What is a leaf chain and why is it used in forklifts?

A leaf chain consists of interlaced steel plates connected by pins. It’s commonly used in forklifts due to its high tensile strength and stability in vertical lifting operations.

2. What’s the difference between PGN’s BL546 and BL634 chains?

The BL546 has a smaller pitch (0.63") and suits moderate-duty tasks. The BL634 has a 0.76" pitch and handles heavier loads, making it ideal for demanding industrial applications. Both chains follow ANSI standards and come with connecting links.

3. How do I choose the right forklift chain?

Check your forklift model, load capacity, and required chain length. Then select a chain that matches those specs. PGN chains are ANSI-compliant and compatible with most forklift brands.

4. How often should I inspect or replace a forklift chain?

Chains should be inspected regularly, especially under heavy use. Signs of wear, elongation, or cracks mean it’s time to replace. Regular lubrication is also essential to prevent failure and extend service life.

5. Are PGN forklift chains compatible with all forklift brands?

Yes. PGN chains follow ANSI standards, ensuring broad compatibility across most forklift models. Just confirm the pitch and load specs before purchasing.

- Choosing a selection results in a full page refresh.