Menu

ER4043

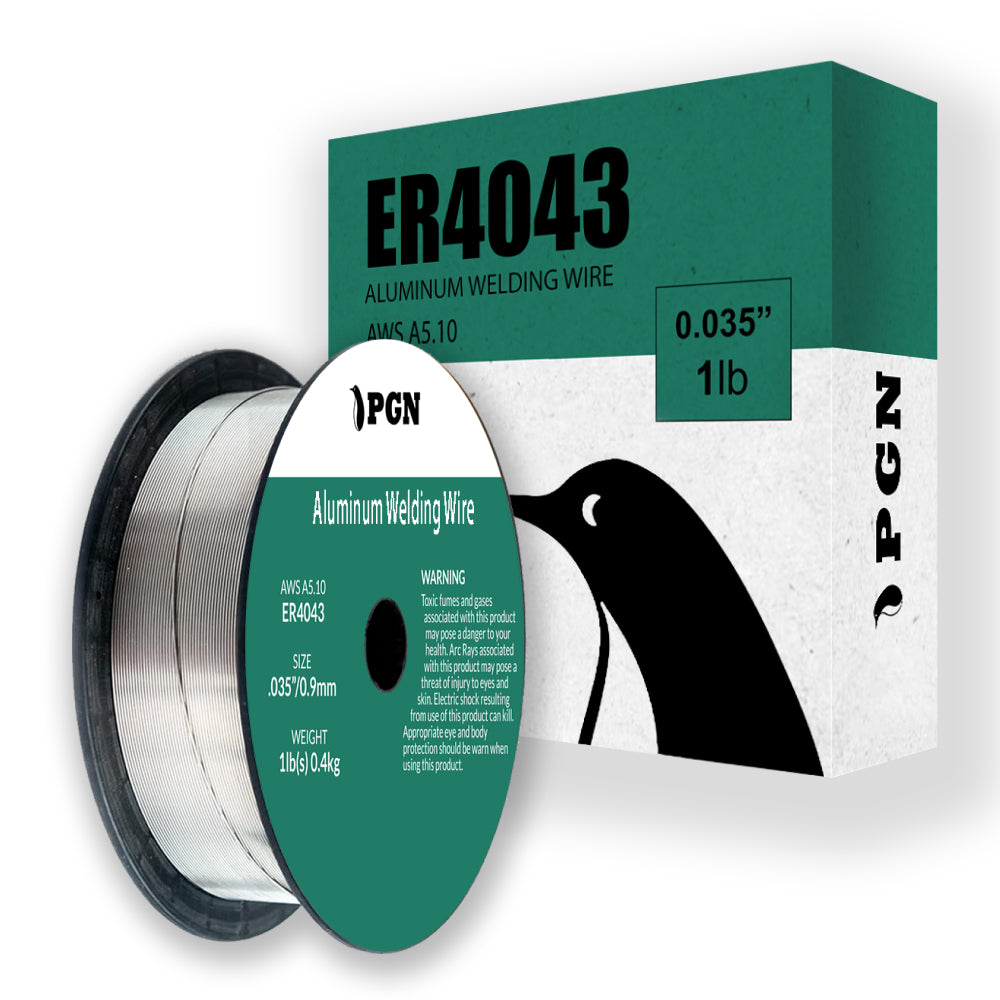

ER4043-0.035" 1lb - Aluminum MIG Welding Wire

Quick View

31% off

ER4043-0.035" 1lb - Aluminum MIG Welding Wire

- Sale price

- $10.95

- Regular price

- $15.95

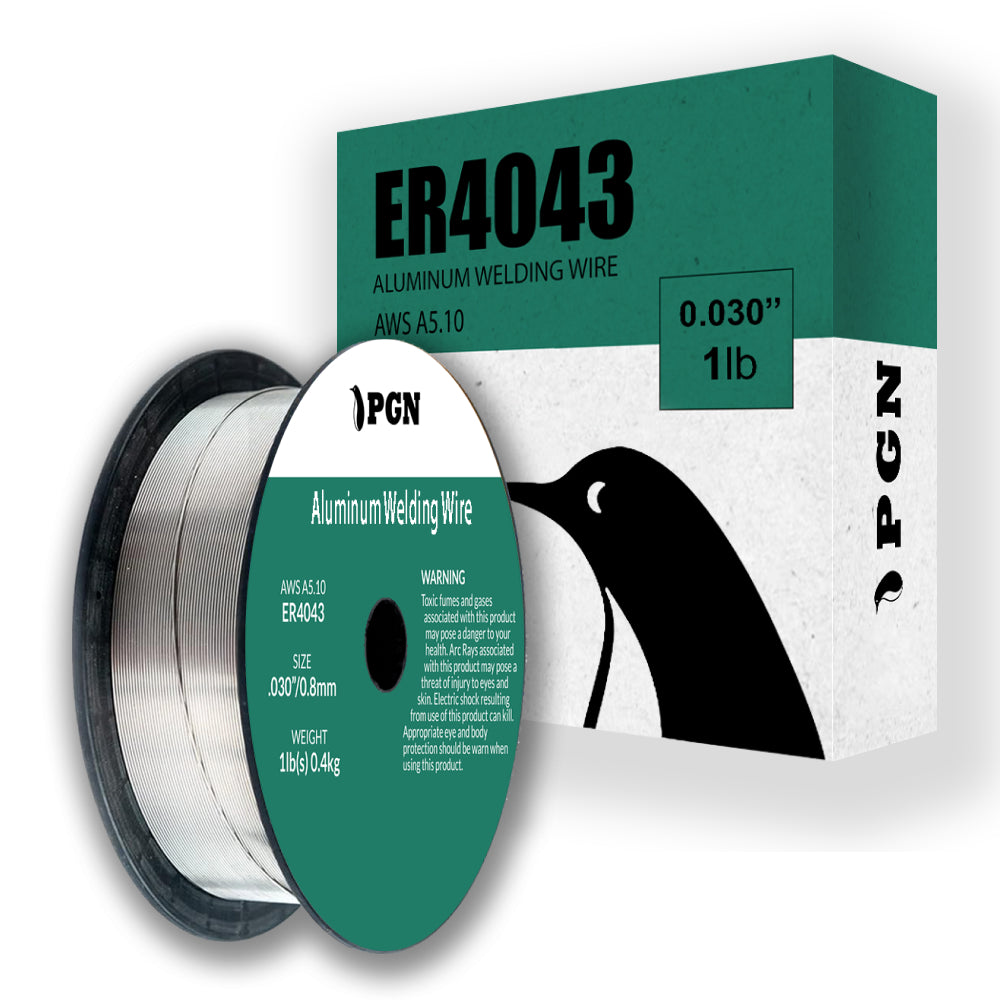

ER4043 0.030" 1lb - Aluminum MIG Welding Wire

Quick View

ER4043 0.030" 1lb - Aluminum MIG Welding Wire

- Price

- $12.95

ER4043 – The Go-To MIG Wire for Aluminum Welding

If you're working with aluminum welding, you know that the right wire makes all the difference. ER4043 is one of the most reliable and versatile options available for this type of application. Known for its excellent puddle flow and crack resistance, it delivers clean, durable welds with a professional finish.

Perfect for light to medium-duty jobs, ER4043 works with a wide range of aluminum alloys and supports all-position welding.

PGN Bearings offers high-performance ER4043 options with fast shipping. Explore the available models and find the best match for your next welding project.

What Is ER4043 and What Is It Used For?

ER4043 is an aluminum MIG welding wire composed of 5% silicon. This chemical makeup makes it ideal for welds with excellent puddle flow, clean finishes, and reduced cracking risks. Its smooth operation and reliable results make it suitable for both industrial use and custom fabrication projects.

This wire is commonly used with aluminum alloys such as 6061, 6063, 5052, 3003, and cast alloys like 356.0 and 443.0. For that reason, it’s a popular choice in automotive repairs, lightweight structural work, manufacturing, and even decorative metalwork.

Another strong point of ER4043 is its consistent appearance, even in multi-pass welds. It’s a versatile and efficient option for professionals seeking strength, precision, and professional-grade results.

How to Use ER4043 for Best Results

To achieve strong and consistent welds, it's important to follow best practices when using ER4043. This aluminum wire is designed for gas-shielded MIG welding (100% argon) and should not be used with gasless machines.

One of ER4043’s strengths is its all-position welding capability. It performs well on T-joints, butt welds, and lap joints, delivering smooth control and a clean finish.

Here are a few key tips to get the most out of it:

-

Prepare the surface properly: remove oils, oxides, or contaminants from the aluminum before welding.

-

Set the machine correctly: adjust voltage and feed speed to avoid burning through the base metal.

-

Pick the right diameter: use 0.030” wire for thinner material and 0.035” for thicker sections.

By following these guidelines, you can take full advantage of ER4043’s performance and achieve clean welds with minimal post-processing.

How to Choose the Right ER4043 Wire for Your Project

To get the best performance from ER4043, it’s essential to choose the right wire for your needs. The correct choice ensures better welds and minimizes post-work corrections.

Choose based on wire diameter:

-

0.030” (0.8 mm): best for thin sheets and precise control.

-

0.035” (0.9 mm): better suited for thicker materials and deeper welds.

Match to your application:

-

Automotive repairs: durable welds with a clean look.

-

Metal art and sculptures: low spatter and clean aesthetics.

-

Light fabrication: consistent feed and reliable results.

-

DIY tasks: practical and beginner-friendly.

Consider the required amount:

-

1lb spools are ideal for small jobs, touch-ups, or casual use.

These quick tips will help you choose the right ER4043 model with more confidence and precision.

Common Applications of ER4043 Wire

ER4043 is widely used across industries where clean, strong aluminum welds are essential. Its silicon-based composition offers great puddle flow and crack resistance, making it a go-to wire for both professionals and hobbyists.

Typical applications include:

-

Automotive repairs: perfect for aluminum panels, mounts, and structural parts with smooth, reliable welds.

-

Metal art and sculpture: enables creative work with clean finishes and minimal spatter.

-

Light manufacturing and structural welding: delivers consistent performance in fast-paced production.

-

Home maintenance and DIY projects: user-friendly and effective in all welding positions.

Thanks to its adaptability, ER4043 remains a trusted solution for anyone working with aluminum across different fields and levels of experience.

Benefits of Using ER4043

ER4043 stands out as a reliable and efficient choice for aluminum welding. One of its key advantages lies in its smooth puddle flow, thanks to its silicon content. This allows for better control during welding, resulting in precise and clean welds with minimal effort.

Its ability to resist cracking is another highlight, especially when working with cast alloys or parts exposed to stress. The low spatter behavior also helps maintain a cleaner work environment and minimizes the need for post-weld cleanup.

Another strength of ER4043 is its compatibility with commonly used aluminum alloys like 6061, 5052, and 3003. This makes it a go-to option across several industries, including automotive, manufacturing, maintenance, and even hobbyist applications.

Finally, the wire feeds smoothly into MIG machines, making it easy to handle regardless of your experience level. Whether you're focused on productivity or weld quality, ER4043 delivers dependable performance every time.

Discover PGN Bearings’ ER4043 Wires

PGN Bearings offers ER4043 wires designed for welders who demand performance, reliability, and professional results. Manufactured to high standards and packaged with care, these options suit both precise and high-penetration applications.

ER4043 0.030” (0.8 mm) – 1 lb Spool

This thinner wire is ideal for lighter welding jobs where control and detail are essential — perfect for sheet metal repairs, home maintenance, and metal artwork.

Key specs and features:

-

Diameter: 0.030” (0.8 mm), excellent for thin materials and fine welds.

-

Weight: 1 lb spool — great for short-term projects and precise use.

-

Alloy: Made with 5% silicon, improving puddle flow and minimizing spatter.

-

Applications: Compatible with alloys like 6061, 6063, 5052, 3003, and cast types 356.0, 357.0, 413.0, 443.0.

-

Packaging: Moisture-resistant film ensures a rust-free and tangle-free experience.

-

Ideal for: Clean visual results, art welding, and light-duty repairs.

If you need control, clean finishes, and versatility for thinner aluminum, this is the right spool for you.

ER4043 0.035” (0.9 mm) – 1 lb Spool

For heavier welds and deeper penetration, this wire offers the strength and consistency required in more demanding applications — whether structural or industrial.

Key specs and features:

-

Diameter: 0.035” (0.9 mm), suitable for thicker materials and strong joints.

-

Weight: 1 lb spool — ideal for frequent, multi-pass welds.Alloy: Contains 5% silicon for crack resistance and smooth flow.

-

Applications: Compatible with a wide range of aluminum alloys including 6061, 5052, and 3003.

-

Packaging: Anti-moisture sealed to prevent corrosion and maintain feed consistency.

-

Ideal for: Structural welding, automotive parts, and general fabrication.

This model is perfect for welders who prioritize power, reliability, and performance on thicker aluminum components.

Why Buy ER4043 from PGN Bearings

The ER4043 wire from PGN Bearings is designed to deliver stable performance, compatibility with multiple aluminum alloys, and consistent technical quality.

Each spool undergoes strict quality checks and is sealed in moisture-resistant packaging, helping prevent rust and feed issues during use.

With operations based in the U.S. and structured for quick delivery, PGN supports efficient logistics and inventory reliability — ideal for workshops, manufacturers, and personal projects where timing matters.

As we mentioned before, one of the key advantages of this wire is its consistency. The 5% silicon content improves puddle control and minimizes cracking and spatter, making it easier to achieve clean welds with minimal rework.

Whether you're welding automotive components, light structures, or handling general repairs, PGN’s ER4043 offers straightforward use, reliable performance, and a solid balance of cost and quality.

Check out the available models and choose the right wire for your next project!

FAQ – ER4043 da PGN Bearings

1. What is ER4043 welding wire used for?

ER4043 is a MIG welding wire made from aluminum alloy with 5% silicon. It’s used to weld alloys like 6061, 6063, 5052, and 3003, offering smooth puddle flow, reduced cracking, and a clean finish.

2. What’s the difference between ER4043 0.030” and 0.035”?

The 0.030” (0.8 mm) wire is better for thin aluminum and precision work. The 0.035” (0.9 mm) wire is suited for thicker materials that require deeper welds.

3. Can I use ER4043 without shielding gas?

No. ER4043 must be used with shielding gas (100% argon). It is not designed for gasless (flux core) welding.

4. What alloys are compatible with ER4043?

ER4043 is compatible with alloys such as 6061, 6063, 5052, 3003, and cast types like 356.0, 357.0, 413.0, and 443.0.

5. Are PGN’s ER4043 wires moisture-protected?

Yes. PGN’s spools are sealed in moisture-resistant film to prevent rust and wire tangling.

6. What is the weight of PGN’s ER4043 spools?

Each ER4043 spool from PGN weighs 1 lb (approximately 0.45 kg).

7. Where can PGN’s ER4043 be used?

It can be used for automotive repairs, light manufacturing, metal art, home maintenance, and aluminum DIY projects.

8. Is PGN’s ER4043 wire beginner-friendly?

While aluminum is not the easiest metal to weld, PGN’s ER4043 offers smooth feeding and arc control, making it a solid choice for beginners.

- Choosing a selection results in a full page refresh.