Menu

ER70S-6 MIG Wire

Product type

Availability

Price

$0

$979.95

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 2 Lbs Spool

Quick View

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 2 Lbs Spool

- Price

- $3.95

ER70S-6 .030" (0.8 mm) Mild Steel MIG Welding Wire - 2 Lbs Spool

Quick View

ER70S-6 .030" (0.8 mm) Mild Steel MIG Welding Wire - 2 Lbs Spool

- Price

- $4.40

ER70S-6 .023" (0.6 mm) Mild Steel MIG Welding Wire - 2 Lbs Spool

Quick View

ER70S-6 .023" (0.6 mm) Mild Steel MIG Welding Wire - 2 Lbs Spool

- Price

- $4.95

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

Quick View

35% off

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

- Sale price

- $18.80

- Regular price

- $28.90

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

Quick View

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

- Price

- $18.95

ER70S-6 .030" (0.8 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

Quick View

47% off

ER70S-6 .030" (0.8 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

- Sale price

- $19.45

- Regular price

- $36.95

ER70S-6 .023" (0.6 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

Quick View

41% off

ER70S-6 .023" (0.6 mm) Mild Steel MIG Welding Wire - 10 Lbs Spool

- Sale price

- $24.75

- Regular price

- $41.95

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

Quick View

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

- Price

- $60.95

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

Quick View

24% off

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

- Sale price

- $63.45

- Regular price

- $82.95

ER70S-6 .023" (0.6 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

Quick View

9% off

ER70S-6 .023" (0.6 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

- Sale price

- $72.42

- Regular price

- $79.95

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 44 Lbs Spool

Quick View

14% off

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 44 Lbs Spool

- Sale price

- $72.45

- Regular price

- $84.70

ER70S-6 .030" (0.8 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

Quick View

2% off

ER70S-6 .030" (0.8 mm) Mild Steel MIG Welding Wire - 33 Lbs Spool

- Sale price

- $74.25

- Regular price

- $75.40

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 44 Lbs Spool

Quick View

17% off

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 44 Lbs Spool

- Sale price

- $78.55

- Regular price

- $94.90

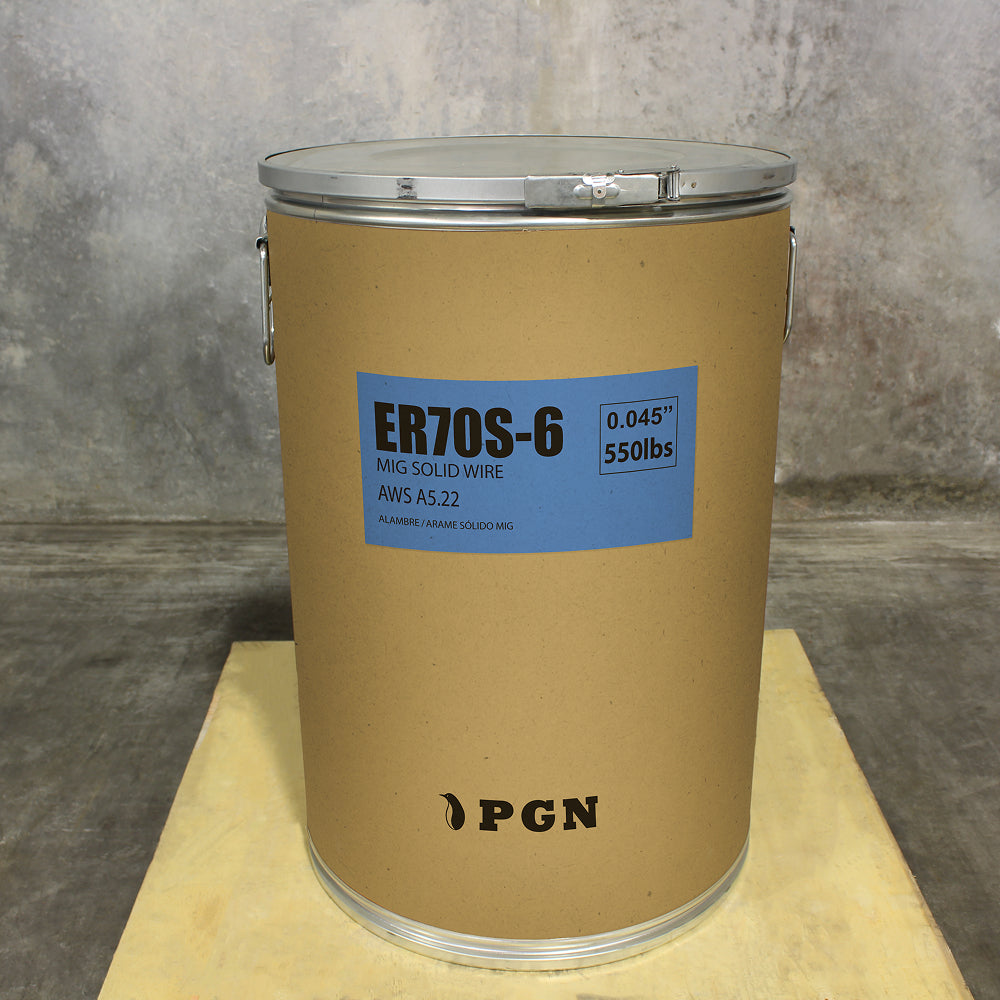

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 550 Lbs Spool

Quick View

ER70S-6 .045" (1.2 mm) Mild Steel MIG Welding Wire - 550 Lbs Spool

- Price

- $890.57

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 550 Lbs Spool

Quick View

ER70S-6 .035" (0.9 mm) Mild Steel MIG Welding Wire - 550 Lbs Spool

- Price

- $979.95

ER70S‑6 MIG Wire: Versatile, Precise, Reliable

ER70S-6 MIG wire is the go-to choice for strong, clean welds with outstanding arc control. Known for its versatility, this wire is widely used in industrial, automotive, and structural applications. It delivers high tensile strength, low spatter, and smooth fusion — even on lightly oxidized surfaces.

At PGN Bearings, you'll find a complete range of ER70S-6 MIG wires, available in various diameters and spool sizes.

Whether you're working on light projects or large-scale welding operations, we have the perfect fit to boost your welding performance.

What Is ER70S‑6?

ER70S-6 is a solid MIG welding wire designed for mild steel. With 70,000 psi tensile strength, it performs well even on slightly rusty surfaces, thanks to its high manganese and silicon content.

It works with shielding gas and supports all welding positions. Also usable as a TIG filler rod, ER70S-6 is a reliable choice for clean, strong welds.

Where to Use ER70S‑6

ER70S‑6 is one of the most versatile MIG wires on the market, making it ideal for professionals working across various welding scenarios. It’s commonly used in structural fabrication, automotive repair, industrial maintenance, and general metal equipment production.

Thanks to its high levels of silicon and manganese, this wire performs well even on surfaces with slight contaminants like rust or mill scale. That’s why it’s trusted in environments where surface prep isn’t always perfect.

One key advantage is its ability to weld in all positions — flat, horizontal, vertical, and overhead — without compromising arc stability. This makes it ideal for complex builds, piping systems, and tight spaces.

Whether for single-pass or multi-pass welding, ER70S‑6 delivers consistent results and a clean finish, making it a reliable choice for professional and industrial use.

ER70S‑6 Advantages

ER70S‑6 stands out for its strong technical performance and everyday reliability. One of its key advantages is a tensile strength of up to 70,000 psi, which ensures solid, long-lasting welds on carbon steel.

Another highlight is its low spatter level, which helps reduce cleanup and delivers a better finish. The arc remains stable, and the fusion stays clean — even on slightly oxidized surfaces — thanks to the high manganese (Mn) and silicon (Si) content that acts as deoxidizers.

The wire also offers excellent puddle control, resulting in smoother, more consistent weld beads with improved visual appeal. This means greater precision, fewer errors, and a more efficient welding process.

For welders who value performance and productivity, ER70S‑6 is a dependable solution.

Choosing the Right Diameter

Choosing the right ER70S‑6 wire diameter is key to achieving the best welding results. Each size serves a specific purpose and should match the material thickness, joint type, and welding position.

-

.023" (0.6 mm): perfect for thin sheet metal and light jobs. Offers more control and reduces the risk of burn-through.

-

.030" (0.8 mm): well-balanced and great for general use, from light to moderate welding tasks.

-

.035" (0.9 mm): the most popular size. Versatile enough for different joints and positions.

-

.045" (1.2 mm): ideal for heavy-duty structures, thicker materials, and high-deposition work.

Always match the diameter to your project needs to ensure proper penetration, arc control, and finish. When in doubt, go smaller for thin materials and size up as needed.

Explore PGN’s Full Range of ER70S‑6 MIG Welding Wire

At PGN Bearings, we offer a complete lineup of ER70S‑6 MIG wires, engineered to meet a variety of welding needs — from lightweight jobs to high-volume industrial applications.

All wires are compatible with shielding gas MIG welding, meet AWS A5.18 standards, and come in moisture-resistant packaging to ensure long-lasting performance.

Check out the main options:

ER70S‑6 .023" (0.6 mm) – 2 lbs

Perfect for thin metal and detailed work. Offers superior arc control with low burn-through risk. Lightweight 2 lb spool makes it easy to store and handle.

ER70S‑6 .030" (0.8 mm) – 2 lbs & 10 lbs

Great for light-to-moderate welding tasks. Choose between a compact 2 lb spool for occasional use or a 10 lb spool for regular work.

ER70S‑6 .035" (0.9 mm) – 2 lbs, 10 lbs, 33 lbs, 550 lbs

The most popular size in our lineup. Provides a balanced mix of penetration and control. Available in small, medium, large, and high-capacity drum formats for all levels of demand.

ER70S‑6 .045" (1.2 mm) – 10 lbs, 33 lbs, 550 lbs

Ideal for heavy-duty welding on thicker metals. The 550 lb drum version ensures continuous feed and strong arc stability with fewer spool changes.

Every option is built for efficiency and reliability. With PGN, you get high-quality welding wire that delivers smooth puddle control, low spatter, and consistent results — shipped fast from our Florida warehouse.

How to Choose and Use ER70S‑6 the Right Way

Getting the most out of your ER70S‑6 wire starts with following a few key practices during use. Here are some practical tips to help you achieve cleaner, stronger, and more stable welds.

1. Match the diameter to your project

-

Use .023" or .030" for thin sheet metal and light-duty work.

-

Go with .035" or .045" for structural welding and higher deposition.

Choosing the right size helps avoid burn-through or poor penetration.

2. Choose the right shielding gas

ER70S‑6 is designed for gas-shielded MIG welding. A 75% argon / 25% CO₂ mix minimizes spatter and improves finish. Pure CO₂ provides deeper penetration, ideal for heavy welds.

3. Store wire in a dry environment

PGN’s packaging is moisture-resistant, but storing your spools in a dry, sealed space prevents oxidation and feeding issues.

4. Adjust machine settings properly

Set voltage, amperage, and wire feed speed according to the diameter and material. This helps control the arc and improve weld consistency.

5. Maintain your welding torch

Keep the contact tip clean and check for silicon buildup. Smooth wire feeding means better weld quality and fewer interruptions.

With the right setup and care, ER70S‑6 delivers reliable performance from start to finish.

Get the Job Done Right with PGN’s ER70S‑6 MIG Wire

Whether you’re welding thin sheet metal or tackling high-volume production, PGN’s ER70S‑6 offers the perfect balance of strength, arc stability, and clean results. With multiple spool sizes and diameters available, there’s a solution for every welding need.

Browse our full selection, pick the right fit for your project, and enjoy fast delivery from a team that knows welding inside and out.

Order now and weld with confidence, precision, and lasting performance.

Frequently Asked Questions About ER70S‑6

1. What does ER70S‑6 mean?

The AWS A5.18 code breaks down as follows: ER stands for electrode/rod, 70 indicates 70,000 psi tensile strength, and S‑6 refers to the alloy content — higher manganese and silicon for better performance on slightly oxidized surfaces.

2. Which wire diameter should I use?

Use .023" or .030" for thin metal and light jobs. Choose .035" or .045" for thicker materials and structural welding. Always match the wire size to your material thickness and application.

3. Does ER70S‑6 require shielding gas?

Yes. It works with gas-shielded MIG welding. A 75% argon / 25% CO₂ mix is the most common. Pure CO₂ is also compatible and provides deeper penetration.

4. Can I use ER70S‑6 for TIG welding?

Yes, when cut into rods, it can be used as a filler material for TIG welding in specific cases. While designed for MIG, it has crossover applications.

5. What’s the difference between ER70S‑6 and ER70S‑2?

ER70S‑6 contains more Mn and Si, making it better for welding on dirty or rusty surfaces. ER70S‑2 is recommended for clean base metals and precise, low-spatter welds.

- Choosing a selection results in a full page refresh.