Menu

Tools

Product type

Availability

Price

$0

$74.04

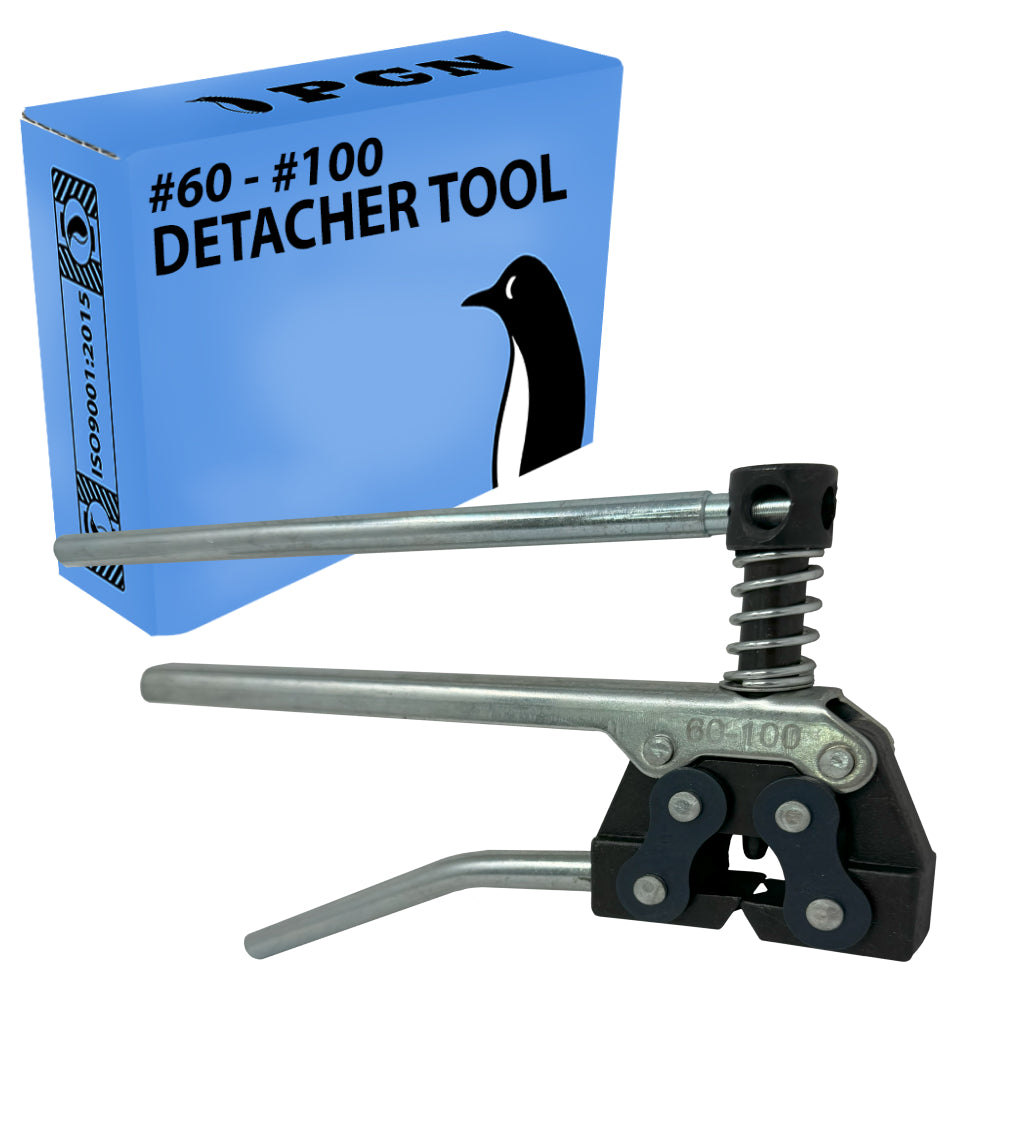

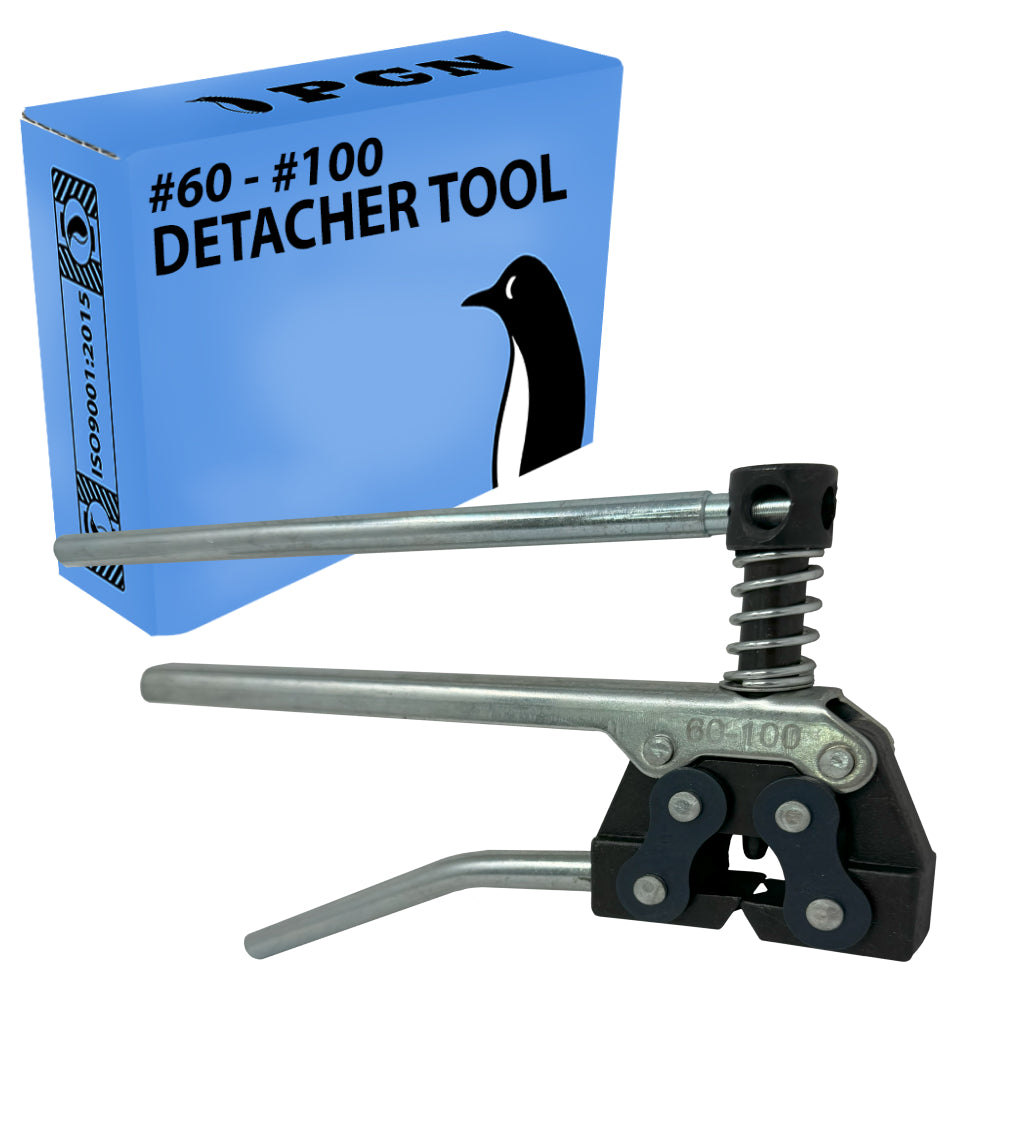

PGN Chain Detacher Tool - Fits Sizes #100 to #180

Quick View

PGN Chain Detacher Tool - Fits Sizes #100 to #180

- Price

- $74.04

PGN Roller Chain Detacher Tool for #420 #425 #428 #525 #530

Quick View

PGN Roller Chain Detacher Tool for #420 #425 #428 #525 #530

- Price

- $7.27

PGN Roller Chain Tool - Fits Sizes #100 to #180

Quick View

PGN Roller Chain Tool - Fits Sizes #100 to #180

- Sale price

- $28.57

- Regular price

- $29.95

Roller Chain Connecting Puller Tool – Fits #60, #80, #100

Quick View

Roller Chain Connecting Puller Tool – Fits #60, #80, #100

- Price

- $12.64

Roller Chain Cutter & Breaker Tool – Fits Sizes #25 to #60

Quick View

Roller Chain Cutter & Breaker Tool – Fits Sizes #25 to #60

- Price

- $11.58

Roller Chain Cutter Tool - Fits Sizes #60, #80 & #100

Quick View

Roller Chain Cutter Tool - Fits Sizes #60, #80 & #100

- Price

- $16.90

Roller Chain Puller Tool - Fits Sizes #25 to #60

Quick View

Roller Chain Puller Tool - Fits Sizes #25 to #60

- Price

- $8.95

Roller Chain Tools – Cut, Detach & Connect with Precision

Roller chain tools are essential instruments used in handling roller chains, which are widely applied in mechanical systems and industrial transmissions.

These tools are designed to perform tasks such as cutting, detaching, pulling, and connecting chain links with accuracy and safety, without damaging the components.

They play a key role in ensuring proper maintenance, quick adjustments, and efficient assembly of chains across various sizes.

These tools are commonly used in industries like manufacturing, construction, agriculture, and transportation — where reliable chain performance is critical to operational efficiency.

What Are Roller Chain Tools?

Roller chain tools are mechanical devices designed to assist in handling industrial chains, especially roller chains. They enable specific tasks like cutting links, separating sections, pulling ends, and connecting new segments accurately and safely.

These tools are essential during chain assembly, maintenance, or replacement, particularly in equipment that relies on chain-driven systems.

The most common types include chain breakers, used to remove damaged or excess links, and chain pullers or connectors, which help align and secure links during installation.

Overall, these tools streamline manual labor and minimize errors that could affect the performance of the chain or the equipment as a whole.

Why Use Dedicated Roller Chain Tools?

Industrial chains operate under high loads and require precise alignment for each link. Using generic or improper tools can lead to structural damage, misalignment, or premature wear.

Dedicated roller chain tools are specifically designed to handle these tasks, offering a precise fit, safe handling, and compatibility with various chain sizes.

These tools also help prevent accidents during maintenance, reduce equipment downtime, and improve the efficiency of link replacement or installation. When properly used, they extend the lifespan of both the chain and the mechanical system it powers.

Choosing the right tools is not just about convenience — it's about ensuring long-term performance and operational safety.

Tips to Choose the Right Tool

Picking the right roller chain tool is easy when you focus on a few key factors. Consequently, you gain efficiency, safety, and longer equipment life.

-

Chain-size compatibility — Match the tool to the chain number (#25 to #180 or #420 – #530). The jaws must grip the link firmly.

-

Intended function — Decide whether you need to break/detach or pull/connect. Each design serves a distinct purpose.

-

Build quality — Look for carbon-steel bodies and an adjustable pin. An ergonomic handle also reduces user fatigue.

-

Ease of adjustment — Smooth threads and clear alignment marks speed up work and protect the links.

-

Simple upkeep — A corrosion-resistant finish allows quick cleaning and safe storage, which extends tool performance.

By following these guidelines, you’ll select the ideal tool to keep your chain system running smoothly.

Practical Usage Advice

Using roller chain tools properly makes a big difference in both performance and system longevity. A few simple practices can enhance safety and ensure precise results.

-

Align the pin carefully before applying pressure. It must be centered on the chain rivet to avoid damage.

-

Apply force gradually, avoiding sudden movements. This reduces the chance of bending links and gives you better control.

-

Don’t over-tighten. A well-aligned tool works efficiently with less effort. If you feel too much resistance, stop and realign.

-

After use, clean the tool lightly and, if needed, apply lubricant to the moving parts.

-

Store in a dry place, away from moisture and dirt, to maintain its condition over time.

With these simple habits, your tool will last longer and make maintenance tasks smoother and safer.

Complete PGN Tools Lineup

PGN Bearings offers a full lineup of high-performance roller chain tools, designed to handle various chain sizes and industrial tasks. Made of heavy-duty carbon steel, each tool delivers precision, durability, and ease of use. Explore the options below:

Chain Cutter & Breaker Tool – Sizes #25 to #60

Designed for fast cuts and link removal on small to mid-sized chains. The top push pin provides accurate rivet alignment without the need for extra tools. Compatible with sizes 25, 35, 40, 41, 50, and 60.

Chain Cutter Tool – Sizes #60, #80 & #100

Built for thicker roller chains. Its reinforced frame ensures safe, clean cuts with minimal effort and excellent control over pressure and alignment.

Chain Puller Tool – Sizes #25 to #60

This compact connector tool helps pull and align links, even in tight spaces. Works with various light-duty chain sizes, including motorcycle-standard chains.

Connecting Puller Tool – Sizes #60, #80 & #100

Engineered for easy link alignment and tension control. The solid steel body provides long-lasting support during installations or adjustments.

Roller Chain Tool – Sizes #100 to #180

Designed for heavy-duty industrial chains. Perfect for joining or tensioning large chains, including #100, #120, #140, #160, and #180.

Chain Detacher Tool – Sizes #100 to #180

Removes tough chain links with minimal effort and no lubricants. The adjustable push pin ensures precise force application on large chains.

Detacher Tool – Sizes #420 to #530

A flexible solution for motorcycle and machinery chains. Supports sizes #420 through #530, with reinforced construction and smooth operation.

Benefits of PGN Tools

Choosing PGN tools means accessing a full range of benefits that go beyond basic functionality. Each model is engineered to meet strict industrial standards, delivering reliable performance, ease of use, and long-lasting durability.

-

Heavy-duty construction: every tool is made of high-strength carbon steel, built to handle pressure and frequent use.

-

Precision fit: adjustable pins and finely machined components help ensure proper alignment and safer operation.

-

Less physical strain: ergonomic designs allow for controlled force application with less fatigue, even on large chains.

-

Wide compatibility: tools support chain sizes from #25 to #180, including key formats like #420, #428, #530, and more.

-

Field versatility: whether cutting, detaching, or connecting links, PGN tools support every maintenance step efficiently.

With PGN, you get tools crafted for professionals who expect top-quality performance in every detail.

Why Choose PGN Bearings?

PGN Bearings supplies purpose-built tools for industrial roller chains, compatible with a wide range of sizes and applications. Each product is made of carbon steel and goes through quality control processes appropriate for mechanical and industrial use.

The catalog includes models designed for tasks like cutting, detaching, and connecting chain links. Tools are shipped directly from the United States, helping ensure access to standardized and reliable maintenance components.

If you're looking for practical tools that match industry standards, browse the full PGN tools collection and find the right fit for your job.

FAQ – Roller Chain Tools

1. What are the main types of roller chain tools?

The most common ones include cutters, detachers, and pullers. Each tool is designed for a specific task such as cutting, detaching, or aligning chain links.

2. How do I know which tool fits my chain?

Check the chain number, such as #25, #60, #100, #428, or #530. PGN lists all compatible chain sizes in the product descriptions.

3. Do these tools require lubrication?

Most PGN tools operate without additional lubrication. Still, light maintenance is recommended—clean after use and apply lubricant to moving parts if needed.

4. Can I use the same tool to cut and connect chains?

No. Each tool is built for a specific function. Cutters are made for link removal, while pullers align and connect chain ends. Using the wrong tool may cause damage.

5. Are PGN tools compatible with motorcycle chains?

Yes. Some models support chain sizes commonly used in motorcycles, such as #420, #428, #520, and #530. Always check the product specifications before purchase.

6. Can I use these tools on rusted chains?

Yes, but extra care is required. Damaged or corroded links need gradual force to avoid breakage. Preventive maintenance is recommended to avoid excessive wear.

7. Where can I buy PGN tools?

You can order directly here on PGN’s website. Just go to the tools page, find the model that fits your chain size, click to view the product details, and add it to your cart.

Then complete checkout by entering your shipping and payment info. Orders ship quickly from the United States.

- Choosing a selection results in a full page refresh.